Overview

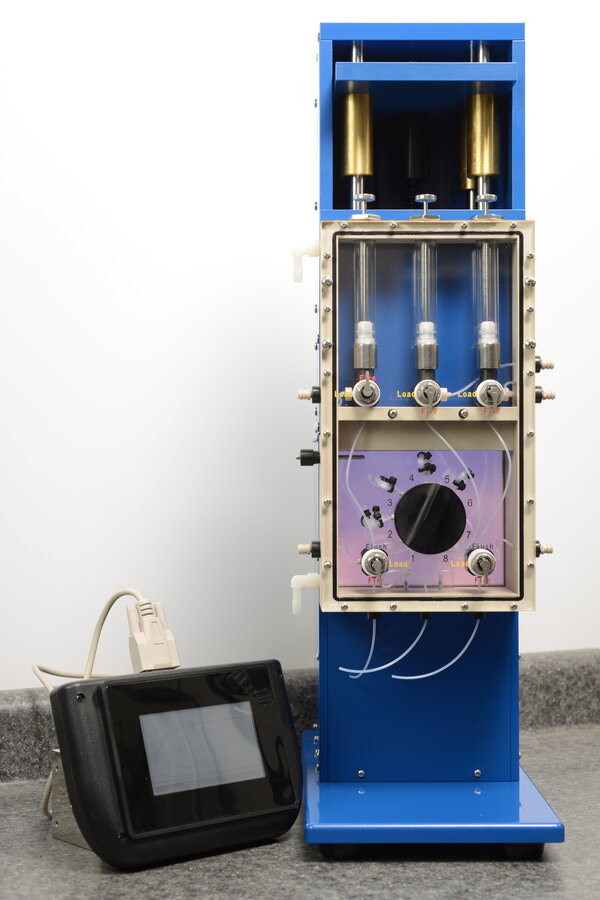

The KinTek RQF-3 represents the international standard for analysis of enzyme reaction mechanisms. This rapid-quench kinetic analysis system enables researchers to examine enzyme reaction pathways with unprecedented precision, minimal sample consumption, and maximum data accuracy.

With reaction times as short as 2.5 milliseconds and sample requirements of just 15-20 µL per shot, the RQF-3 delivers the performance you need to understand complex enzymatic mechanisms.

Key Features

- Computer-controlled servo motor for precise, reproducible timing

- 8-way rotating valve for selecting different reaction delay lines

- Double Delay Quench standard (three mixing events, two programmed reaction times)

- Sealed keypad with LCD display resistant to acids, bases, and radioactive materials

Sample Efficiency

The RQF-3 maximizes the value of every microliter:

- 20 data points from 300 µL total sample

- Flush-load-collect cycle in under 2 minutes

- Complete 20-point time course in approximately 45 minutes

- Minimal waste through efficient sample line design

Chemical Quench-Flow Methodology

Core Principle

The chemical quench-flow method mixes reactants, passes them through a precisely-controlled reaction delay line, then encounters a chemical quenching agent (typically acid or base) to instantly terminate the reaction. Quenched samples are collected for subsequent analysis by HPLC, mass spectrometry, gel electrophoresis, or scintillation counting.

Reaction Timing Control

Precise reaction times are achieved by varying the delay line length and flow rate. The RQF-3 achieves reaction times from 2 to 100 milliseconds through its innovative eight-way valve system that selects different delay line lengths.

RQF-3 Innovation

KinTek's rapid quench-flow design minimizes sample waste through several key innovations:

- Small Tubing Loops: 15-20 µL delay lines reduce waste

- Eight-Way Valve: Select delay times without manual valve changes

- Computer-Controlled Servo Motor: Push-pause-push mode for precise timing

- Extended Timing Range: From 2 milliseconds to indefinite durations

The push-pause-push operation provides exceptional timing accuracy: the motor fires rapidly for mixing, pauses for the programmed reaction time, then fires again to quench the reaction.

Double Delay Quench Capability

The standard double-delay configuration enables three mixing events:

- First Mixing: Enzyme + substrate combine

- First Delay: Reaction proceeds for programmed time

- Second Mixing: Third reactant added (optional)

- Second Delay: Additional reaction time (computer-controlled)

- Quenching: Chemical quench terminates reaction

This flexibility enables complex pre-equilibration experiments, sequential substrate addition, and investigation of ordered binding mechanisms.

Sample Collection and Analysis

Quenched samples exit the instrument for immediate or delayed analysis. The chemical quench effectively "freezes" the reaction, allowing:

- Quantification: Measure substrate/product concentrations

- Identification: Characterize transient intermediates

- Verification: Confirm optical stopped-flow measurements

- Complementary Data: Combine with stopped-flow for complete mechanisms

Applications

The RQF-3 is the instrument of choice for researchers studying:

- Enzyme Mechanism Analysis: Pre-steady-state kinetics, burst phases, transient intermediates

- DNA/RNA Polymerase Studies: Nucleotide incorporation, fidelity mechanisms, proofreading

- Protein-Ligand Binding: Association/dissociation kinetics, competition experiments

- Multi-Step Reaction Pathways: Sequential catalysis, intermediate accumulation

Integration with KinTek Explorer

Combine RQF-3 chemical quench-flow data with stopped-flow data in KinTek Explorer for:

- Multi-technique global fitting with a single mechanistic model

- Mechanistic validation using complementary techniques

- Complete picture combining optical and chemical measurements

Related Products

- Auto SF-120: Automated stopped-flow for optical detection (120 µL total)

- SF-300X: Flexible stopped-flow with double-mixing (20 µL per reactant)

Combine stopped-flow and quench-flow data in KinTek Explorer for comprehensive mechanistic understanding.